Innovators of metalworking lubrication systems

The most diverse offering of lubrication systems available anywhere!

LSP Systems

- Airless Spray Lubrication

- Roller Coater Lubrication

- Low Pressure Mist Lubrication

- Coolant, Air, and Manifold Products

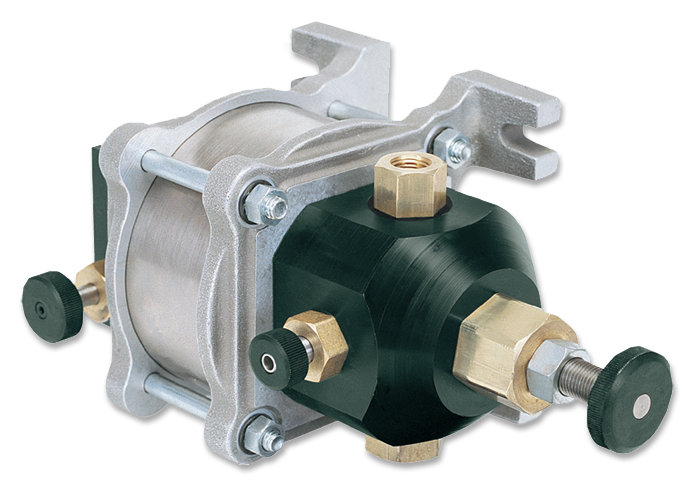

Airless Spray Lubrication

Precise, controlled dispensing of fluids in an airless spray.

- PresSpray

Economical, positive-displacement for spray lubrication with distribution of fluid split between one to many nozzles. For light to heavy fluids. Learn more - PresSpray Plus

Premier, positive-displacement spray lubrication with independent nozzle volume control and timing for ultimate control. For light to heavy fluids. Learn more - MaxaMizer

Computer controlled time-pressure system for easy operator interface. For light fluids. Learn more

Roller Coater Lubrication

Efficient roller lubrication systems from 1 inch to 72 inches wide.

- FloaterCoater

Heavy duty systems for 12 to 72” wide material. Rolls float with passline of material! Learn more - MiniCoater

Lighter duty systems for material width up to 12”. Learn more - B-Coater

Specifically designed for blanks – hand fed or integrated with robotic handling. Learn more - FinCoater

Ideal for applying light coatings to fast moving thin gage materials (i.e. fins). Learn more

Low Pressure Mist Lubrication

Micro dosing low-pressure lubrication systems with 1 to 6 ejectors per system.

- MeterMizer

Used for Minimal Quantity Lubrication(MQL) in primarily cutting applications. Learn more

Coolant, Air, and Manifold Products

Three unique products offerings.

- Mist Coolant

Economical, venturi-based coolant applicators for manual cutting applications. Learn more - Blastmatic

Air ejection system to reduce set-up time, shop noise, and utility costs. Learn more - ExpandaFold

Modular manifold system for air or fluid. Learn more

The Leader in Lubrication Technology

LSP Industries, Inc. is a manufacturer of high quality lubrication systems. Products range from PressSpray® Air-Less Spray Systems and FloaterCoater® roller coaters for the metal stamping industry. OptiMist® mist coolant systems serve the machine tool industry. Our job is to provide the best quality lubrication systems for a variety of environments from the job shop to automated production environments. We invite you to talk with our Application Specialists to determining how we can help control your lubricant use and costs. Specialty product lines include ExpandaFold® Manifoldable On/Off Valves for easy time-saving manifold solutions, BlastMatic® Air Blow-off Parts Ejection System for simplified part removal, and Replaceable Head Soft and Brass Hammers for cost-effective non- marring striking power.

Products

Soft Head Hammers

These versatile hammers offer the best features for most applications. The heads are cast of LSP's Soft Alloy, Brass, and Malleable Iron materials. The handles, consisting of a sturdy steel shank with a contoured safety-grip molded permanently onto it, are extremely durable. The grip, of a cushion synthetic rubber, has a comfortable, no-slip feel when grasped. Five different size heads will fit on our standard handle saving up to 70% in cost.

Lamson Oil

Trust Lamson Oil Company to be the source for your stamping lubricant needs.

When you choose Lamson, you get an extensive array of quality products - including the finest straight oils, specialty oils, synthetic lubricants, vanishing oils and water soluble oils - along with the expertise to make the perfect selection for any job.