Individual Blank Lubrication System

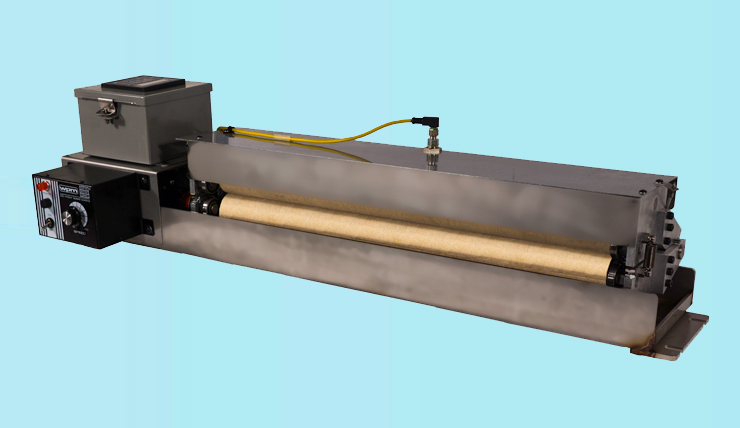

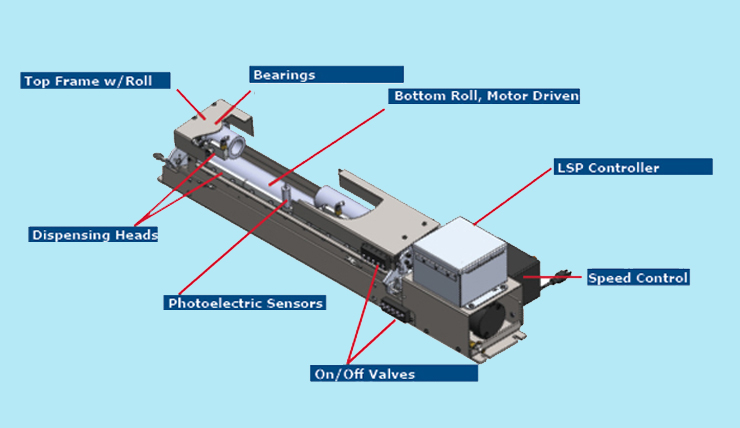

The B-Coater is designed specifically for lubricating blanks. Computer controlled for just the right amount of lubricant, the B-Coater eliminates spray bottles, brushes and rollers and ensures that every blank will be lubricated. It increases the speed of production, improves die life, lowers down time, reduces rejects and saves money. Manifolds allow the user to shut areas in need of lubrication on and off.

Computer controlled, the B-Coater will dispense most viscosity lubricants in the quantity needed. When a blank is moved into the rolls, a photo electric sensor activates the rollers and lubricant dispensers. The blank will be grabbed and automatically moved through the rolls while being lubricated. The B-Coater is capable of handling up to .375-thickness material. After the blanks go through the B-Coater, they are they are deposited on the out conveyor on the exit side of the B-Coater and ready to go into the press.

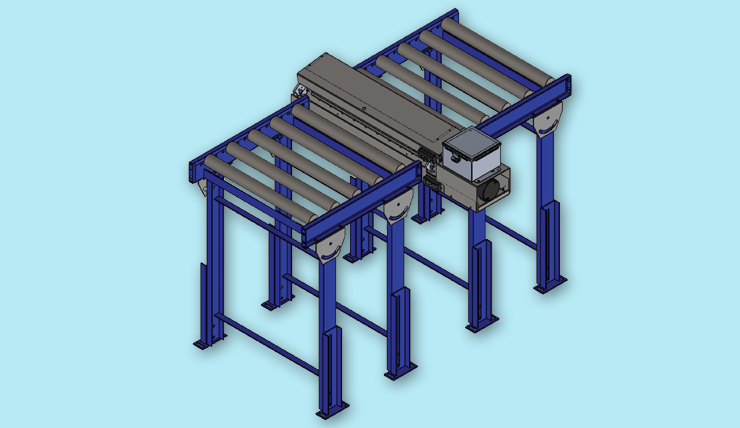

Heavy Duty Conveyor Tables

Sizes from 12" to 48" Wide

The Best for Blank Lubrication

Have a Question?

Complete the form below.